ONEROCK

READY TO USE MICROCEMENT

ONEROCK is a next-generation microcement designed to deliver a flawless aesthetic finish and superior durability on any type of surface. This ready-to-use product stands out for its advanced formula, ensuring exceptional performance both indoors and outdoors, making it suitable for residential, commercial, and industrial projects.

One of the most outstanding features of ONEROCK is its total impermeability, making it the ideal solution for wet areas such as bathrooms, kitchens, spas, or even outdoor spaces exposed to harsh weather. Additionally, its high resistance to abrasion and impact guarantees durability in high-traffic or heavy-use areas without compromising its original appearance.

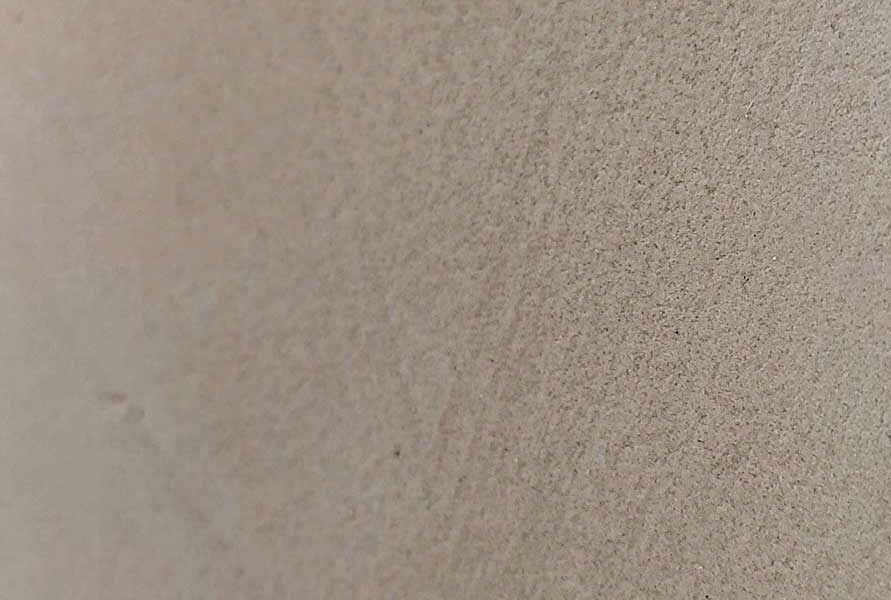

The aesthetics of ONEROCK are defined by its natural finish, adding a modern and elegant touch to any space. Available in a wide range of colors and textures, this microcement allows for customization of each project to meet the client’s needs and preferences, seamlessly blending into any architectural style.

Natural Aesthetics

Simulates a natural beach

Personalization

It can be adapted to any architectural or landscape design.

High Durability

Long-lasting materials, resistant to abrasion and UV rays.

Non-slip surface

Ensures safe use on wet surfaces.

No waste

The material is 100% used. There are no mixtures that harden and are thrown away.

ONEROCK S

ONEROCK M

ONEROCK L

ONEROCK XL

ONEROCK S

ONEROCK S is the finest-grain microcement, perfect for smooth, elegant, and easy-to-maintain finishes. This finish delivers a uniform and refined surface, ideal for contemporary styles without compromising mechanical and chemical resistance.

FORMAT 15 kg

GRANULOMETRY 0,125 mm

DENSITY 1,63 g/cm³

CONSUMPTION 0,3 kg/m²

MAX THICKNESS 0,3 mm

ONEROCK M

ONEROCK M is a medium-grain microcement, ideal as an intermediate layer or as a finish that balances texture and smoothness. It offers a versatile aesthetic that highlights its natural appearance while maintaining high resistance levels.

FORMAT 15 kg

GRANULOMETRY 0,20 mm

DENSITY 1,63 g/cm³

CONSUMPTION 0,45 kg/m²

MAX THICKNESS 0,5 mm

ONEROCK L

ONEROCK L is a coarse-grain microcement that combines mechanical and chemical resistance with a more pronounced texture. It can be used as a base layer or for rustic and natural-style finishes, making it perfect for high-performance projects.

FORMAT 15 kg

GRANULOMETRY 0,40 mm

DENSITY 1,63 g/cm³

CONSUMPTION 0,75 kg/m²

MAX THICKNESS 0,8 mm

ONEROCK XL

ONEROCK XL is the ready-to-use microcement with the coarsest grain size, designed to regularize surfaces and provide structural strength to the system. It is ideal for base layers that require initial leveling and maximum durability, while maintaining the natural look that defines ONEROCK.

FORMAT 15 kg

GRANULOMETRY 0,60 mm

DENSITY 1,63 g/cm³

CONSUMPTION 1 kg/m²

MAX THICKNESS 1 mm

ONEROCK APPLICATION METHOD

1. Surface Preparation

Proper base preparation is essential to achieve a perfect result:

The surface must be clean, dry, and free of dust, grease, loose paint, or any contaminant that could affect the microcement’s adhesion. If there are cracks, imperfections, or irregularities, they must be repaired before proceeding.

It is recommended to lightly sand the surface to increase roughness and improve product adhesion. Sanding residues should be removed with a vacuum or a damp cloth, allowing the surface to dry completely before continuing.

2. Mesh Placement and Primer Application

Mesh: It is recommended to place a fiberglass mesh over the surface to reinforce it, reduce the risk of cracks, and improve system durability, especially for irregular surfaces. For smooth and sound surfaces, it is optional.

Primer: Apply a uniform layer of PRIMER or PRIMERQUARTZ using a roller or brush. This ensures optimal adhesion of the microcement to the substrate.

The primer drying time is approximately 30–60 minutes, depending on environmental conditions.

3. Application of ONEROCK XL or L (Base Layer)

First layer:

ONEROCK XL or L should be applied directly with a flexible metal trowel, spreading it evenly over the entire surface.

The drying time is 6 to 12 hours, depending on temperature and humidity conditions. Once dry, the surface should be sanded with 40-grit sandpaper to remove imperfections and level it.

Second layer (optional): If necessary, and depending on the surface, a second layer can be applied following the same procedure to ensure a uniform base.

4. Application of ONEROCK M or S (Finish Layer)

First layer:

ONEROCK M or S is used according to the desired texture: M for more textured finishes and S for a finer result. The material is spread evenly with a flexible metal trowel.

Once dry, it should be sanded with 120-grit sandpaper to achieve a smooth surface.

Second layer:

A second layer is applied using the same product, sanding again once dry to ensure a uniform, silky, and natural finish.

5. Final Sealing and Protection

To protect the surface and ensure the system’s durability:

Two coats of VARNISH W (or VARNISH DSV for higher water resistance) are applied. It is important to respect the drying time between coats.

Additional Recommendations

Always perform a preliminary test on a small area to check the color and product compatibility. Apply ONEROCK in controlled conditions, with temperatures between 10°C and 25°C and moderate humidity levels.

Clean all tools immediately after use to prevent the product from hardening on them.

This procedure ensures that the ONEROCK system delivers professional results with a durable, aesthetic finish.