TERRAZZONE APPLICATION METHOD

1. Surface Preparation

Proper surface preparation is essential to ensure a quality finish. The surface must be clean, dry, and free from dust, grease, loose paint, or other contaminants that could affect the adhesion of the material. Any cracks, imperfections, or irregularities must be repaired before proceeding.

It is recommended to lightly sand the surface to increase its roughness and improve the product’s adhesion. Dust generated from sanding should be removed with a vacuum or a damp cloth, and the surface should be allowed to dry completely before proceeding.

2. Primer Application

It is recommended to apply a fiberglass mesh over the surface to reinforce it, which helps reduce the risk of cracks and improves the system’s durability, especially on irregular surfaces. For completely sound and smooth surfaces, applying the mesh is optional. The system has some flexibility, which helps prevent potential cracks.

Next, apply a uniform layer of PRIMER or PRIMERQUARTZ using a roller or brush. The drying time of the primer is approximately 30 to 60 minutes, depending on environmental conditions.

3. APPLICATION OF ONEROCK L (BASE COAT)

ONEROCK L should be applied with a flexible metal trowel, spreading it evenly across the entire surface. The drying time is between 6 and 12 hours, depending on temperature and humidity. Once dry, the surface should be sanded with 40-grit sandpaper to level and remove any imperfections.

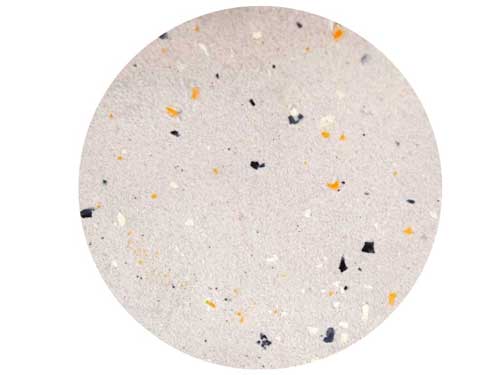

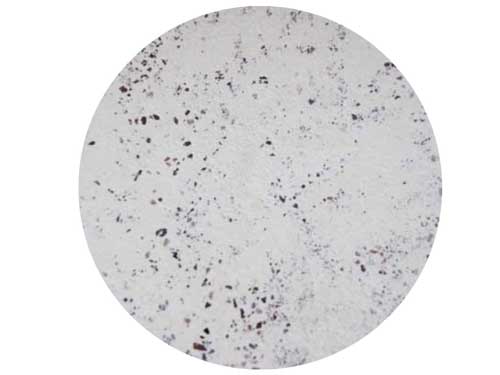

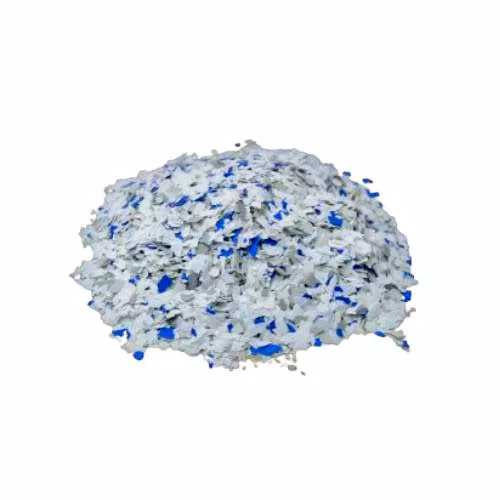

4. APPLICATION OF TERRAZZONE (FINISHING COAT)

Apply a 2mm thick layer of TERRAZZONE over the prepared base. This material should be spread evenly with a flexible metal trowel. After it has completely dried, the surface should be sanded with 40-grit sandpaper to reveal the terrazzo colors and achieve the desired effect. The material is highly resistant to abrasion, so it is important to use quality abrasives and apply more pressure when sanding.

5. Sealing and Final Protection

Once the sanding process is complete, apply two layers of VARNISH W or VARNISH DSV to seal and protect the surface. It is crucial to respect the drying times between each layer to ensure proper protection.

6. Additional Recommendations

Always conduct a test in a small area to verify compatibility and the final finish of the system. It is recommended to work under controlled conditions, with temperatures between 10°C and 25°C and moderate humidity levels. Additionally, tools should be cleaned immediately after use to prevent the material from hardening on them.

This procedure ensures that the TERRAZZONE system delivers a continuous terrazzo finish, with a professional, durable, and aesthetically pleasing result.